Many companies struggle with what to measure to improve the performance of their companies. I’ve seen some blog posts that just give a long list of manufacturing KPIs for the reader to chose from.

Deciding on your manufacturing KPIs is as important as thinking through your system to track, review and correct.

You are choosing manufacturing KPIs in order to improve your performance. To do so, I recommend companies follow these 4 steps.

- Decide on what KPIs to track for you business

- Develop a system to track the KPIs you’ve decided are important

- Develop the discipline and meeting rhythm to review the data on a regular basis

- Decide when your KPIs indicate that you need to take corrective action

How To Decide What Manufacturing KPIs To Track

As I’ve said before, I am not a big fan of picking from a list of KPIs since your company’s KPIs should be linked to your company goals and strategy.

So how do you decide which KPIs to track?

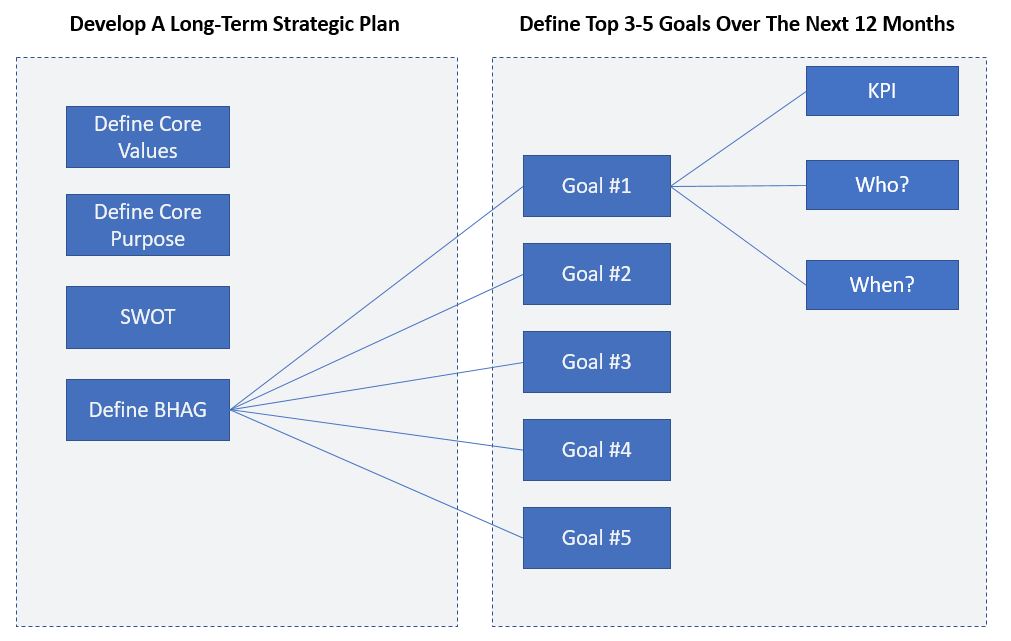

Take a look at the picture below. You can see how choosing a KPI is actually the third step in a process. It all starts with developing a long-term (at least 5 year) strategic plan which articulates where you want to lead the business over the next 5 years.

Once that’s complete, you need to define your top 3-5 company goals.

Each goal should be SMART. In doing so, there will be an apparent “measurable” component to the goal. If not, re-think the goal. That measurable piece becomes your KPI.

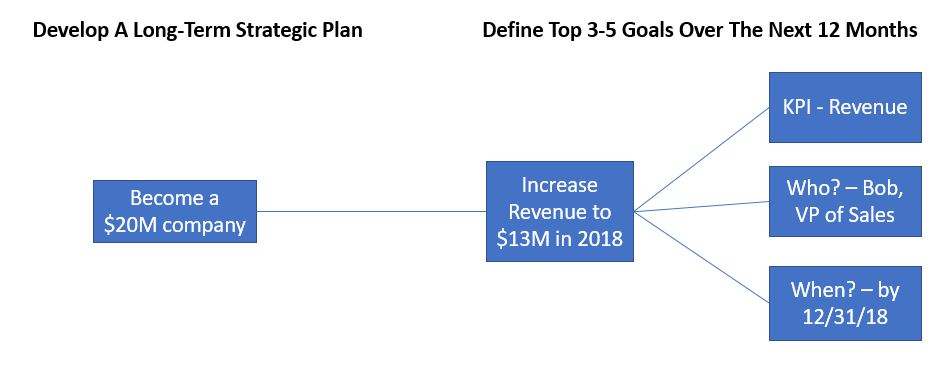

In the example below, you can see how we’ve linked the long term strategic goal (which I like to call your quantitative BHAG) to “become a $20M company” to a company goal of “increasing revenue to $13M” in 2018. The goal for 2018 has a “KPI=Revenue”, a “Who’s responsible=Bob” and a due date = 12/31/18.

Is “revenue” the only KPI you’ll track? Absolutely not. You should track some leading and KPIs like “bookings”. You also want to track the goals of your salespeople who all will contribute to the $13M in revenue.

I think you get the picture. The main point being, you need to start at the top. Where are you bringing the company long-term and who is responsible for each goal. How will you measure success? That’s your KPI.

If you need help with this process (developing a strategic plan and mapping out your goals, we can help).

Developing A System To Track Your Manufacturing KPIs

Just as important as determining a group of KPIs to track is developing a system to track them. If you’re not going to track a KPI, you might as well not have that KPI in the first place.

Many of the customers we work with have used multiple Excel spreadsheets to track their KPIs. Excel is an incredibly flexible tool, but it can fall short when is comes to tracking multiple KPIs.

Remember that each goal should have at least one KPI associated with it and at least one owner. Excel does not do a great job of linking KPIs to goals. In addition, if you have multiple people accessing the same Excel doc, it can cause versioning problems. To work around this, I’ve seen manufacturing companies use multiple Excel docs which makes tracking even more difficult.

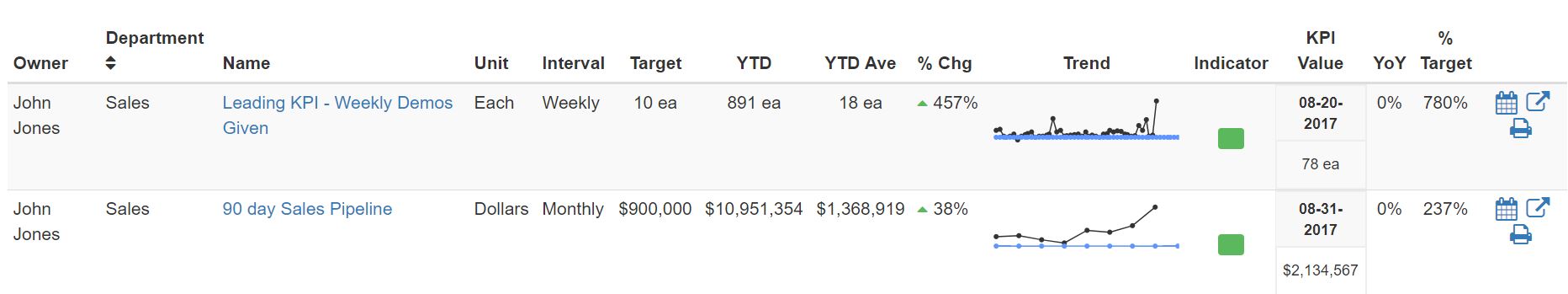

Here comes my shameless plug. Check out our software. Every member of your team can have a login and manage their own KPIs. We’re happy to do a demo. It’s FREE!

Even more importantly, everyone on the team can see the top company goals and how success is measured AND if the company goal is in the red, yellow or green.

Developing The Discipline To Review The KPIs On A Regular Basis

Ok, now you have a list of KPIs you are tracking. These KPIs are directly related to your goals and you are updating them weekly, monthly or quarterly.

You need some regular meeting discipline to review the data. The reason you are tracking the KPIs in the first place is to achieve your goals. It’s to improve your business.

I’ll give you a very personal example. A few years ago I found out I had Type II Diabetes. I set to work, adjusting my diet and tracking everything I ate. I was able to achieve the result I wanted (losing weight and reversing the diabetes diagnosis). Why did this happen? Because I had a daily meeting rhythm of tracking my weight and tracking my calories and carbs. I noticed that I would often eat MORE that I thought. Especially when I didn’t track the results.

Having a meeting rhythm in place is critical for success. It it painful at times? Yes. Are there going to be times when your team doesn’t want to meet, when you don’t want to meet? Yes. Do it any way.

Deciding When Your KPIs Indicate That You Need To Take Corrective Action

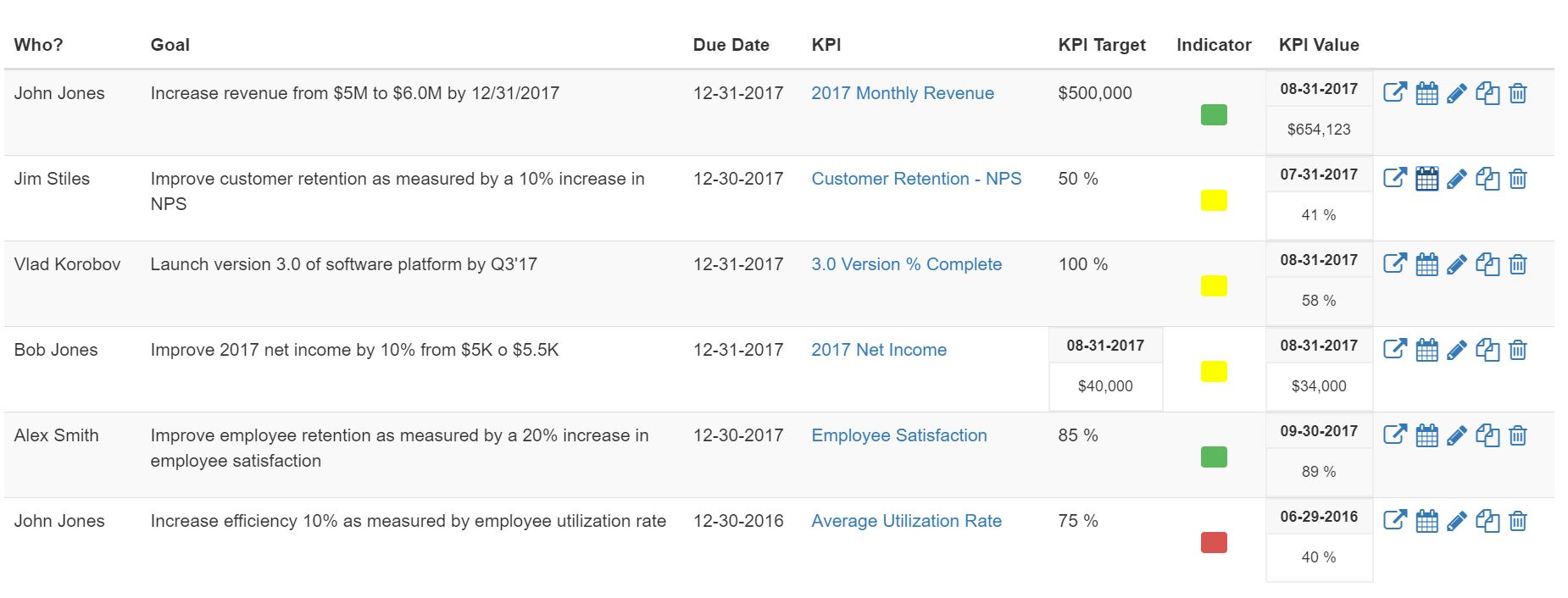

I left out an important part of determining your KPIs, determining your Target and Thresholds.

This deserves it’s only section, because you need to decide ahead of time when you need to be alarmed about a KPI. You do this by setting thresholds for each KPI.

It’s not enough just to set a target.

Going back our revenue KPI, what happens when our revenue goal for the month is $1M and we only brought in $900K. Is that bad? How bad is it? This is determined by creating a red, yellow and green threshold.

If the result is in the “green” then there is no need to take action. If it’s yellow or red, it’s time to dig deeper and determine the root cause. Use the collective intelligence of the team to brainstorm about how to fix the problem.

So if you’re looking to develop manufacturing KPIs for your business (or any other business):

- Strategically deciding what KPIs to track

- Develop a system to track the KPIs you’ve decided are important

- Develop the discipline and meeting rhythm to review the data on a regular basis

- Decide (in advance) when your KPIs indicate that it’s time to take corrective action

…and of course we’d love to help, just click on the button below.

{{cta(‘b9a3ed81-299b-48e2-8fb9-4e9557ca62b9’)}}